Source: Hakko

If you still do not know the scientific way to cleaning soldering iron tip then you are lagging in daily household management and end up draining money to professional technicians which you might have saved otherwise. Cleaning soldering iron tip is a fundamental skill for anyone working with electronics, and although it might seem like a small task you need to know this whether you are a seasoned hobbyist, a modern homemaker, a busy professional, or a professional technician.

Keeping your soldering tip in top condition is crucial for achieving high-quality solder joints and extending the life of your tool. This guide delves into the why, how, and when of cleaning soldering iron tip, peppered with statistics and insights to give you a comprehensive understanding along with disclosing, what is the best soldering iron tip cleaner, how to clean soldering iron tip without flux, how to clean oxidized soldering iron tip, how to clean soldering iron tip with sponge, how to prepare Solder tip cleaner paste and bulk of soldering iron tips.

Table of Contents

What is soldering iron tip? What is a soldering iron used for?

Solder is a popular and widely used fusible alloy that technicians and soldering professionals use to link electrical components like computers, cellphones, and a diverse range of electronic circuits together. For accurate assembly and maintenance, soldering irons are indispensable in the fields of electronics, plumbing, and metalworking.

A soldering iron tip is a metal point that is heated at a high-temperature range of 200°C to 480°C (392°F to 896°F) for melting solder and uniting two different metals. A wide range of soldering iron tips are available in the market among which conical, chisel, and bevel tips are among the popular ones to accommodate a range of soldering operations.

The robust material of the iron tip ensures the required endurance and heat transfer in any soldering operation and is usually copper-covered with iron and you should employ a strict maintenance routine for ensuring the effectiveness and longevity of the soldering iron tip such as cleaning and tinning for best results. Users also need to purchase a synthetic soldering iron tip cleaner from the market or prepare a DIY soldering iron tip cleaner to make sturdy connections on circuit boards, guaranteeing the operation of gadgets ranging from computers to cell phones.

The Importance of Cleaning Soldering Iron Tip: Say Goodbye to Poor Solder Joints with Soldering Iron Tip Cleaner

The importance of cleaning soldering iron tip is multifaceted according to the American National Standards Institute (ANSI) which reported that one of the main causes of soldering failures is inadequate soldering iron tip maintenance.

Electricians, plumbers, and metalworkers have agreed that a clean soldering iron tip that is not oxidized is essential during crucial soldering operations because it promotes effective heat transmission, allowing the tool to work at its best which in turn reduces the need for replacements and downtime lowering costs and boosting output. Experts in the field claim that a properly maintained soldering iron tip can extend the life of your soldering iron by up to 50%.

The solder and other metallic components you are working with encounter the tip of your soldering iron during the soldering process hugely impacting the accurate degree of heat transfer and over time flux and solder residues, as well as oxidation accumulate on the tip, resulting in poor solder junctions and component damage. It is critical to maintain a clean soldering iron tip with a soldering iron tip cleaner because research from the IPC (Institute for Printed Circuits) indicates that approximately 30% of soldering-related problems in industrial environments are caused by poor tip quality.

When to Clean Soldering Iron Tip: Boost Performance and Longevity?

Knowing when to clean your soldering iron tip is key to ensuring the optimal efficiency and longevity of your soldering iron tip and ensuring successful soldering operations in diverse industrial settings. You should clean the tip before you start the soldering process to ensure that you start with a clean surface, which can help prevent contamination from the eventual process and permit the required degree of heat transfer.

Also, during soldering operations, if you notice that the solder is not flowing smoothly and melting or that you are having to apply excessive pressure, it might be time to take extra care of your soldering tip or effectively clean the tip. After the soldering process is complete do not forget to clean the tip to remove any residues and oxidation that have built up during the process.

A study by the Journal of Electronic Packaging found that soldering tips that are regularly cleaned before and after the soldering process, bear a 20% higher rate of successful solder joints compared to those that were cleaned less frequently underscoring the importance of regular soldering iron tip maintenance.

Methods for Cleaning Your Soldering Iron Tip: Keeping Your Iron Tip Clean

There are several methods for cleaning soldering iron tips and you can adhere to your chosen method based on your cleaning needs and convenience, and each of the methods come with its advantages and recommended practices. Here is a rundown of the most used techniques of cleaning soldering iron tip:

How to clean soldering iron tip with sponge-Sponge Cleaning

If you clean the soldering iron tip with an easy-to-use damp sponge or widely available wet-cellulose sponge, you will be able to remove most residues but consider that an overly wet sponge can cause thermal shock or if not properly wiped off, the tip will not heat up fully eventually harming the tip. If you use the sponge for cleaning the soldering tip wrongly, you can also experience that the tip is cooling down too soon or leaving behind particles, so before cleaning, always preheat the iron tip and make sure the sponge is just barely damp.

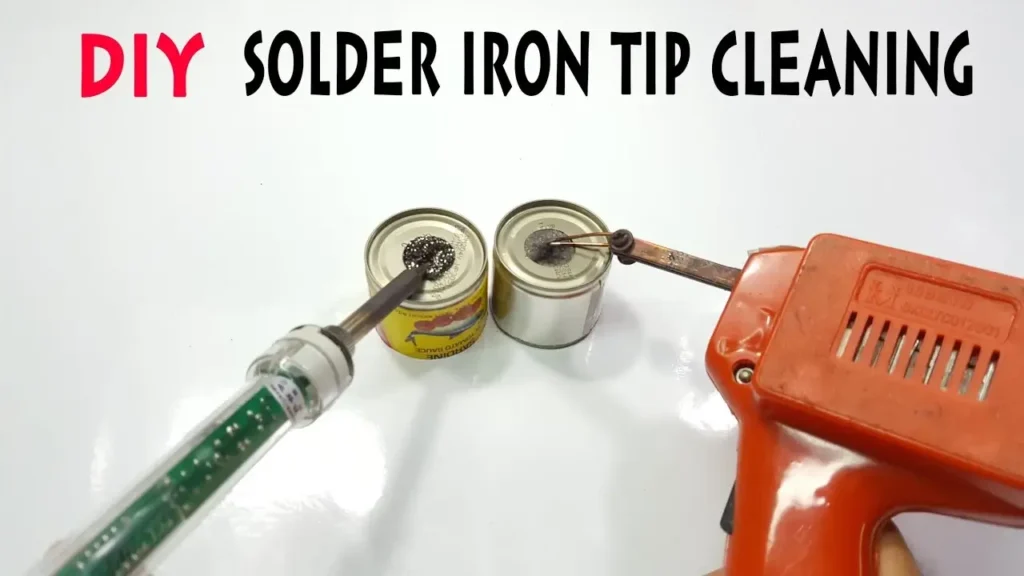

How to clean soldering iron tip with brass wire sponge-Brass Wire Sponge

When you are cleaning soldering iron tip with a coiled brass cleaner or a brass wire sponge then oxidized particles and other remaining residues are scraped off by passing the tip through the brass wire. This approach of cleaning the soldering tip is advantageous over others as it does not cool the tip as much as using a moist sponge and is less likely to result in thermal shock.

It should also be noted that brass wire sponges should not be used very vigorously otherwise you might experience wearing down of the tip and to ensure optimal cleaning process to get rid of collected residues, you should clean the brass sponge regularly.

How to clean soldering iron tip with solder tip cleaner paste-Chemical Cleaning

You can also use homemade soldering iron tip cleaning pastes or DIY soldering iron tip cleaners customized specifically for this process otherwise synthetic cleaners often include chemicals and fluxes to aid in the dissolution of oxidized particles and other metallic contaminants, that are efficient in removing any type of tough residues. However, since soldering tip cleaning chemicals are caustic, so you must adopt extra precautions to make sure the tip is optimally cleaned and does not contain any chemical residue and while doing this you should adhere to the manufacturer’s directions.

Tips for Maintaining a Soldering Iron Tip: Soldering Iron Tips

Tinning the Tip: After using and cleaning, always tin your soldering iron tip with a thin layer of solder to prevent its encounter with moisture and subsequent oxidation and store it in the lowest temperature possible as numerous research studies have pointed out that soldering iron tips that are regularly tinned last up to 25% longer than those that are not.

Avoiding Excessive Heat: High temperatures coupled with a moist atmosphere escalate oxidation and consequently, your soldering iron tip wears away prematurely. So, whenever you are performing any soldering tasks, perform it at the lowest temperature possible to ensure longevity an optimal maintenance of the soldering iron tip.

Proper Storage: If you want to ensure optimal longevity of the soldering iron tip, then if not in use, store your soldering iron at a low temperature abiding by the manufacturer’s guidelines, or cover the tip to prevent its encounter with moisture and subsequent oxidation.

Using Quality Solder: Always purchase premium-quality solder over low-quality or corrosive solder since the quality of the solder significantly affects the tip’s longevity and cheap-quality solder leads to faster degradation of the iron tip.

Why Regularly Cleaning Soldering Iron Tip Matters: Troubleshooting Common Issues?

If you notice poor solder flow, it may be due to oxidation of your soldering iron tip or extreme dirt buildup which appears as dull gray or black then you can restore its original state and efficiency with regular cleaning and tinning. If the oxidation is very bad and it runs deep then you might not have any other way left but to replace the tip or use an aggressive soldering iron tip cleaner available in the market that comes with harsh chemicals.

Before proceeding with cleaning with a harsh chemical you should clean the tip and re-tint it and you should replace the tip if it sustains physical damage, such as deformation, erosion, or extreme dirt buildup. To reduce damage to the soldering iron tip you should focus on regularly maintaining it and setting up a maintenance schedule.

The Ultimate Guide to Cleaning Soldering Iron Tip: Conclusion

A seemingly insignificant but important part of working in electronics, plumbing, and metallurgy, as well as ensuring successful soldering operations in a variety of industrial settings, is keeping the tip of your soldering iron clean. There are several methods available to clean soldering iron tips, and you can stick to the method of your choice depending on how much residue needs to be removed, how convenient it is, and your cleaning needs while considering that each method has its own benefits and best practices.

You should ensure optimal performance and prolong the life of your soldering iron tip by comprehending the significance of routine cleaning, utilizing appropriate techniques, and adhering to best practices. In place of synthetic cleansers, which frequently contain chemicals and other harmful substances, you can also use homemade soldering iron tip cleaners or DIY soldering tip cleaning pastes developed especially for this purpose while on the contrary, the chemicals and fluxes included in synthetic cleaners, are effective in eliminating even the most stubborn residues, helping dissolve oxidized particles and other metallic impurities.

You can achieve smoother and more successful projects by taking good care of your soldering iron tip, which can yield dependable, high-quality results.

FAQs

What is the best soldering iron tip cleaner?

A brass wire sponge is the ideal soldering iron tip cleaner because it optimally cleans without overstretching the tip or producing thermal shock and increases soldering efficiency by 20%. Using a brass sponge regularly and applying flux sometimes can guarantee you the best soldering tip cleaning results and minimize the need for tip replacements.

How do you prepare DIY soldering iron tip cleaner?

If you want to prepare DIY soldering iron tip cleaner then make a paste by combining equal parts baking soda and salt with a tiny amount of water to make a homemade soldering iron tip cleaner. After applying this paste to the hot soldering tip, use a soft brush or a gentle microfiber cloth to gently scrub it clean to remove up to 25% more oxidation than just a basic moist sponge.

How to clean soldering iron tip without flux?

If you are wondering how to clean soldering iron tip without flux, then you can use fine-grit sandpaper or a brass wire sponge to clean the tip of a soldering iron without flux. To get rid of oxidation and dirt, gently brush the tip with the brass sponge after heating it to operating temperature to increase the tip lifespan by 15%.

How to clean oxidized soldering iron tip?

To optimally clean the oxidized soldering iron tip, you should heat the tip of the soldering iron to its operating temperature before scrubbing the oxidation off with a brass sponge or specialized tip cleaner as soon as possible to increase the quality of the solder bond by up to 30% but to see more effectiveness you should not forget to apply a modest amount of flux before cleaning. According to studies, eliminating oxidation.

How to clean soldering iron tip with steel wool?

If you are wondering how to clean soldering iron tip with steel wool then gently brush the tip with steel wool combined with regular tinning as using only steel wool can be abrasive, which may reduce the tip’s lifespan as research data indicates that excessive usage of steel wool might impair tip lifespan by up to 15%.

How to clean soldering iron tip with sandpaper?

A soldering iron tip can be cleaned by gently rubbing it with fine-grit sandpaper to get rid of build-up and oxidation while to prevent tip damage in the process, it is imperative to use very fine grit—1000 grit or more. Consider using the sandpaper not too vigorously since research published in the Journal of Electronic Packaging suggests that tip longevity may be reduced by as much as 20%.

How to use flux to clean solder tip?

To use flux to clean solder tip, you should apply a tiny amount of flux right to the hot tip of a soldering iron and gently wipe it with an uncontaminated cloth or brass sponge to clean it and after a few minutes, only oxidation and residues will get dissolved by the flux. To ensure the best cleaning and effectiveness, make sure the tip has been warmed before applying.

For the past five years, I’ve been engaged as an SEO content writer, specializing in crafting engaging blog posts. My focus lies in meticulously exploring and evaluating household cleaning appliances, particularly those integrated with cutting-edge and emerging technologies.